Advantages

Home>

Advantages

Lost wax casting

It is one of the oldest casting techniques and has been used in various forms more than 5,000 years.

By using this technique,wax pattern would be made according to the item shape, so that high dimensionally accurate and intricate parts could be produced.

Benefits:

> Fine surface finish, more precise

>Greater design freedom

>Near net shape, close tolerances

>Excellent mechanical propertiesL

>Lower initial tooling costs

>Wide choice of alloys

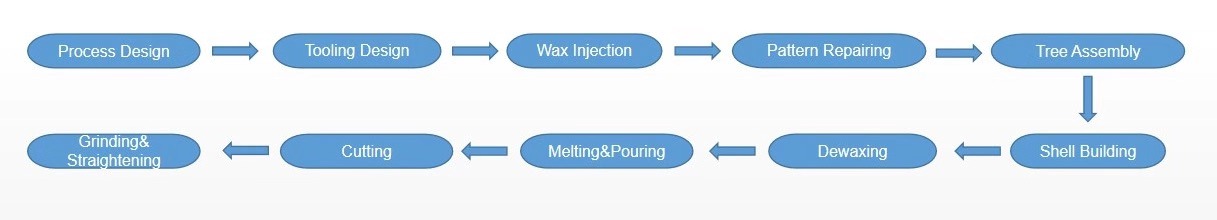

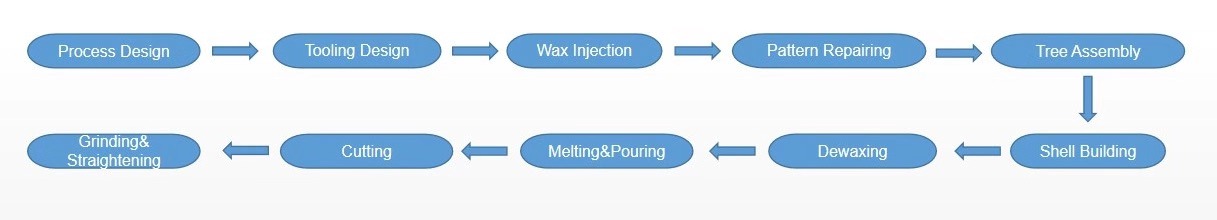

Process:

Material: Carbon Steel, Alloy steel, Stainless steel

Application Field: Automotive, Hydraulic system, Mining machinery, Food machinery,

Construction machinery,offshore

Single Unit Weight: 5g-150kg/PC

Casting tolerance: ISO8062 CT7 to CT9

Casting surface roughness: ≥Ra6.3um

Machining Capability:CNC

Heat Treatment:Solid solution, normalizing, annealing, quenching and carburizing

Surface treatment:Zinc plating, Hot-dip galvanization, Painting(wet pating, powder coating)

Contact us here for more information about VES

Contact:

Cellphone:+86(0) 180 1357 7772

Email:info@vescast.com

Tel: +86 180 1357 7772

Tel: +86 180 1357 7772

Email: info@vescast.com

Email: info@vescast.com