Advantages

Home>

Advantages

Silica sol casting

It has more precise tolearnce and more smooth surface than lost wax casting. It can achieve the thin wall like 3mm. Due to the high precision of this technique, it is highly suited to convert conventional produced products into castings with minising the additional operations by reducing the weight of the final product.

Benefits:

>Precise tolerance

>Possibility for thin wall parts

>Very good looking for surface finish

>Small items can be casted very clearly.

>Wide choice of materials

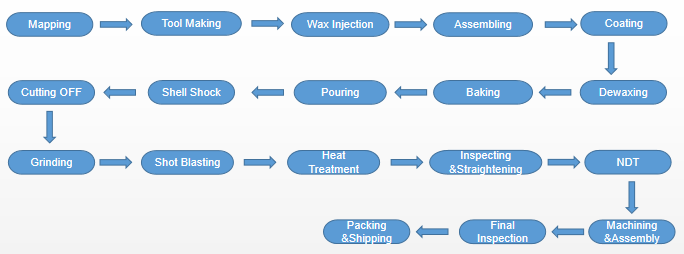

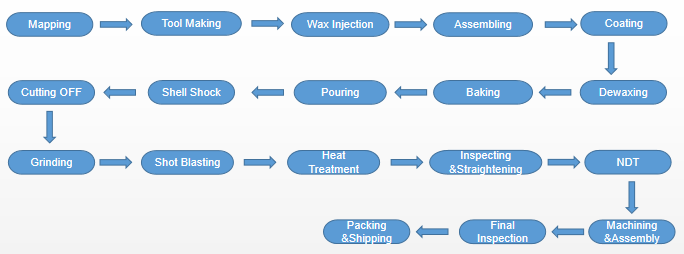

Process:

Material: Carbon Steel, Alloy steel, Stainless steel

Application Field: Automotive,Construction machinery,railway,Agriculture machining, Mining machinery,offshore

Single Unit Weight: 1g-30kg/PC

Casting tolerance: ISO8062 CT5 to CT6

Casting surface roughness: ≥Ra3.2um

Machining Capability:CNC

Heat Treatment:Solid solution, normalizing, annealing, quenching and carburizing

Surface treatment:Zinc plating, Hot-dip galvanization, Painting(wet pating, powder coating),Mirror polishing,Chrome plating

Contact us here for more information about VES

Contact:

Cellphone:+86(0) 180 1357 7772

Email:info@vescast.com

Tel: +86 180 1357 7772

Tel: +86 180 1357 7772

Email: info@vescast.com

Email: info@vescast.com